A small-town factory that was on the verge of bankruptcy is about to revolutionize global cooking with its innovative technology. It is Vermicular.

About Vermicular

Sibling Business Owners Who Saved a Long-established Town Factory, Aichi Dobby

Aichi Dobby is a long-established casting manufacturer founded in 1936 in Nagoya, Aichi Prefecture, Japan. “Vermicular,” is a bland of a made-in-Japan enameled cast iron pot, which was born from the desire of Dobby’s third-generation brothers to create the world’s best product from a local factory.

Originally, as this company name suggests, the company had a history of developing and producing “Dobby-machines,” a type of weaving machine. However, with the decline of the Japanese textile industry, they downsized their operations and managed to survive as a subcontractor for industrial parts.

To save from this crisis, Kunihiro Hijikata, one of the sons of their president, joined the company in 2001, and his younger brother, Tomoharu, joined in 2006, in an effort to rebuild their business.

Development of unique products utilizing existing technologies

They succeeded in earning a certain stable profit from their existing business. However, since they only had a subcontracting business at the time, they decided that they should develop their own products and build a new business portfolio.

Tomoharu then learned that cast iron, their product, was suitable for cookware. Further investigation revealed that while foreign-made cast iron enameled hot pots were popular in the cookware market of Japan, stainless steel and aluminum cookware that is airtight and can be used for waterless cooking was more highly rated.

Cast iron has excellent heat conductivity and heat storage properties, making it a suitable material for cooking utensils, but stainless steel and aluminum are superior in terms of sealing properties. He thought that Aichi Dobby, with its casting and precision machining technologies as a manufacturer of dobby machines, could produce enameled cast iron pots with high sealing performance.

Focus on the highest quality in the world

Of course, development was not easy. After about a year of repeated prototyping and information gathering, they were able to produce a prototype of enameled cast iron pot with the same performance level as existing French one.

At the time, the financial crisis of 2007–2008 was beginning to have a negative impact on their business. Tomoharu, who had conceived the idea, was concerned about the burden on the company’s management and proposed early commercialization, but his brother, President Kunihiro Hijikata, was adamantly opposed and appealed as follows:

“It is meaningless to make what is already available. It is only by focusing on the world’s best quality that we can be proud of Japanese manufacturing and craftsmanship.”

In 2010, finally, they managed to launch the “Vermicular Oven Pot Round” 22 cm, made of enameled cast iron.

Vermicular Oven Pot

Triple Thermal Heating Technology

Exclusive to Vermicular, Triple Thermal Heating creates a dynamic environment in which each ingredient’s natural flavor profile can thrive. Their innovative trifecta of thermal ingenuity transforms a meal from something immediately gratifying into a dish you’ll eagerly anticipate cooking again.

Heat Conduction – The Oven Pot distributes and retains heat remarkably well, allowing ingredients to sear beautifully while the ridges on the bottom surface ensure ingredients are not overcooked.

Radiant Heat – Once heated, the Oven Pot generates radiant heat, sustained by the enamel coating, which penetrates ingredients, cooking them from within while keeping their beautiful appearance intact.

Steam Convection – The Oven Pot’s signature precision seal utilizes steam convection, which is the current created when hot and cool molecules interact, to cook food gently and evenly.

Made-in-Japan

It is extremely difficult to cut 3 mm thick cast iron with high precision and maintain the precision even after three enamel baking cycles at 800 °C, which can be achieved through the accumulated experience of the craftsmen and their strong passion for creating great products.

Casting Process – First, iron melted at 1500 °C and mixed with various metals is poured into specially adjusted sand molds. After cooling, the cast irons are removed from the molds and carefully polished one by one by their craftsmen. They require more delicate techniques than normal industrial products, in terms of strictly regulating the composition and the temperature and speed at which the iron is poured.

Machining Process – The cast iron is then subjected to precision machining process after various surface treatments, in which their craftsmen can grind the cast iron to an accuracy of less than 0.01 mm by their delicate adjustments based on the experience and intuition.

Precision machining of oven pot round cast irons, which has a wall thickness of only 3 mm, requires skill in adjusting the grinding one by one, with feeling the difference in sound and vibration when they are struck.

Enameling Process – In the final process, there are three times that they are sprayed by the glaze, dried, finished and fired at 800°C.

In particular, the uniform spraying is so important that requires skills to adjust according to temperature and humidity.

Musui-Kamado

The Origin is “Rice Cooker”

Rice is a staple food in Japan. while most japanese people cook in rice cookers, some prefer to do in hot pots, who often say,

“Rice cooked in Vermicular Oven Pot tastes better than in any rice cooker.”

They guessed that the ideal rice cooker would be their own oven pot with high airtightness made possible by the precision of their Made-in-Japan. Realizing that the problem with pot cooking is the heat level, they developed a special pot heater that enables kamado-like heating with simple operation, which has been launched in Japan from 2016 as “Vermicular Rice Pot”.

In the Japanese market, the focus was on how to cook rice better, but for the global roll-out, that was on waterless cooking, roasting and low-temperature cooking functions. In 2019, as the world’s first enameled cast iron automatic induction cooker, Vermicular Musui-Kamado has been launched in the U.S.

“Pot” + “Heater” = “Musui Kamado”

The main feature of this product is a fusion of an enameled cast iron pot and an induction heater. Pots can cook rice more deliciously, but lack the reproducibility of taste due to the difficulty of controlling the heat.

The solution to this problem was the idea of surrounding the pot with an induction heater. And, this not only took the reproducibility of good rice cooking to the extreme, but also brought innovation to other aspects of cooking. For example, even roast beef, which is known to be difficult to control in terms of temperature, can be done with this product using just a simple touch of a button.

Furthermore, the pot part was originally developed based on the Oven Pot, and one of its valued features is that it can be used as a pot as it is and cook with its sealing and heat retention properties.

4 Cooking Modes

Musui-Kamado has four cooking modes as below:

1: MED (445°F)

2: LOW (300°F)

3: EXT LOW (230°F)

4: WARM (90-200°F)

These modes can be changed via an intuitive touch screen. In each mode, the pot is heated to a specified temperature. WARM mode can be adjusted between 90-200 °F in 1 °F steps. They also have each off-timer function.

Superior Functional Design

Musui-Kamado has won numerous design awards. Notable awards include A’Design Award & Competition 2019 in Italy and iF Design Award 2019 in Germany. As these awards show, this product is well designed down to the smallest detail, not only in terms of appearance but also functionality.

For example, knobs. Most common enameled pots are designed with a knob-like handle in the center of the lid. However, as these knobs are screwed together, there is a screw head on the back of the lid, and food dirt can easily collect on this uneven surface.

However, this product has no knobs or other small parts and the pot is molded in one piece, making it very easy to wash after use.

Frying Pan

Frying pans are essential utensils for cooking and are used very frequently. However, despite the wide variety of materials and sizes, there are many restrictions on use, and it is often difficult to know which frying pan to choose.

Vermicular frying pans are likely to eliminate this problem.

Innovative Technology to Remove Water from Food

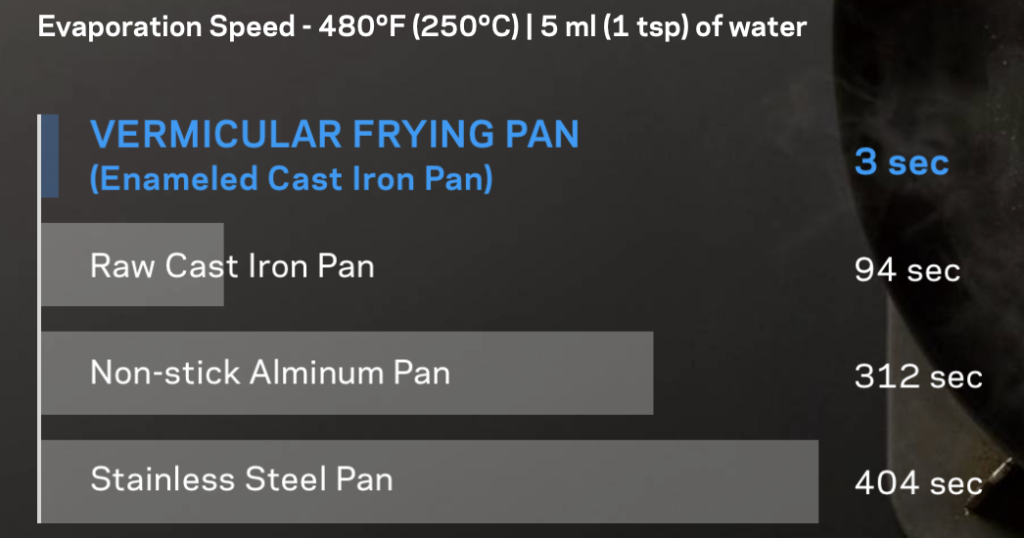

Their frying pan was developed with the aim of creating the world’s best one that can concentrate the natural flavor of food. To achieve this, their focus was on how to remove the water from the food. They had recognized that the reason stir-fries cooked by professional chefs taste so good is that the excess moisture from the ingredients is quickly evaporated with a high-heat source and pan-shaking techniques.

Therefore, they developed a frying pan that instantly evaporates excess water by combining enamel, which has special properties that allow it to absorb water, and cast iron, which has very high heat storage properties. The innovation is evident as follows:

The Vermicular Frying Pan can evaporate water in three seconds, which is 100 times faster than excellent heat conductors’ aluminum frying pans.

Rapid evaporation of moisture makes the surface of the food on the pan crispy and locks the flavor of the food inside. And like the Oven Pot, the powerful far-infrared rays heat food from the core without destroying its tissue.

Easy to Use, and Beautiful

The Vermicular Frying Pan realizes easy-to-use and a pleasure to use from the user’s view, in addition to the innovative technologies.

1.5 mm thick – Usually cast iron pans need to be 3-5 mm thick, but thanks to outstanding processing technology, they can be as thin as 1.5 mm, making them lightweight.

Wood’s handle – Frying pans are used every day. For this reason, the handles are made of wood, which is comfortable in the hand and does not transfer heat like steel. The unique fastening structure also makes it extremely difficult to loosen the joint with the frying pan body.

Detergent Washable – The enamel coating means that it does not peel off easily even after daily use and does not rust like steel frying pans. They can also be cleaned with the detergent you normally use.