Japanese culture has recently been attracting a lot of attention abroad. Anime and other subcultures are popular, but Japanese food is extremely popular due to the growing health consciousness. And now, Japanese kitchen knives are attracting a lot of attention from foreigners.

This article introduces kitchen knife makers that we recommend, along with the origins and history of the three major knife-producing regions in Japan.

Sakai City, Osaka

Forging Techniques Cultivated by Constructing Ancient Tombs

Sakai knives have a history of 600 years, but it is said that their origins are date back to the construction of ancient tombs in the 5th century. There are a lot of ancient tombs around Sakai city, including the Mausoleum of Emperor Nintoku, the largest forward-rectangular ancient tomb in Japan, and it is believed that wrought iron technology was introduced at that time to manufacture the tools used to build them.

This was taken over as Brade-manufacturing from the end of the Heian period, and knives for chopping tobacco imported through the Nanban(Japan-Portugal) trade flourished in the Muromachi period (1336-1573). The first guns imported by the Portuguese in 1543 were also manufactured here. This high level of technology attracted the attention of authorities at that time, such as Oda Nobunaga.

Particularly, The Tokugawa Shogunate in the Edo period (1603-1867) valued the high quality of this product, and to distinguish it from other production areas, it was exclusively monopolized under the special mark “堺極” (Sakai-Kiwame, Ultimate Sakai) by them.

These forged knives are distinguished to have single-edged construction.

Traditional Japanese Knife for Professional Use

There are two main types of cutlery product: the forged type, which is made by hand by craftsmen, and the machine-made one, which is punched and molded by special machines. Sakai’s knives specialize in the former, which uses a technique of “forging” to heat the soft iron or steel as materials at high temperatures and to beat them with a hammer or similar tool.

These forged knives are distinguished to have single-edged construction, which can make the cutting edge so sharp to cut food easily and keep their faces more beautiful. They can also cut through soft foods such as Sashimi without breaking their fibers or cells, so the flavors of the ingredient can be locked inside. Furthermore, it is also functional that the cut food is easy to release from the blade.

In Japan, a food culture has developed in which fish and vegetables are more important than meat, which is called “Washoku”. In order to preserve the flavor of fresh ingredients, kitchen knives have also developed in their own unique way. In other words, Sakai’s knives support the Washoku that is now attracting attention around the world.

#1: Jikko Cutlery(實光刃物)

Jikko Cutlery has been carrying on the tradition and technology of Sakai cutlery for more than 120 years since 1900 AD, when Itaro Jikko started manufacturing cutlery. Their main feature is their outstanding sharpness.

They have worked in conversation with the professional chefs who actually use the knives to create the overwhelming sharpness and the final sharpening that keeps it sharp for a long time. Today, they are used by more than 100,000 chefs in well-known restaurants, ryotei and hotels, and by chefs in more than 30 countries abroad.

Here are the Japanese kitchen knife that professional chefs hope to use one day. It’s “Honyaki”.

©Jikko Cutlery, Honyaki, Seiji(Blue Steel)

Normal Japanese knives are made from a combination of steel and soft iron, whereas honyaki knives are made from steel only. This process is said to resemble that of Japanese swords, hence the name honyaki. This is extremely expensive because its production process is very difficult and craftsmen are limited.

However, its sharpness is outstanding, its durability is very good and it is a beautiful knife to look at, just like a Japanese sword. It may be something that only those who have mastered cooking can appreciate.

Octopus Knife 330mm

Product type: the tip-maru octopus of the “Mizuyaki Honyaki Series”

Manufacturer: Yamawaki Cutlery

Availability: BECOS

Seki City, Gifu

Japanese Swords

The blade is the quintessential representation of Japanese tradition, discipline, and craftsmanship. It is often thought of along with romanticized images of the samurai. Today, Japanese steel is prized for its unparalleled quality and versatility.

Although the long blades of traditional Japanese weaponry like the “katana” and the “tachi” are far less a focus of production, the very same principles and techniques apply to this very day. And luckily for us, we can experience the age old tradition of forging these world renowned treasures.

Japan remains one of the leading producers of the finest cutlery in the world and one very particular region has maintained its position at the forefront of the industry for hundreds of years.

Seki City is a rural town located near the geographic center of the country’s main island. Although landlocked to any of the coasts, the area is fortified by mineral rich mountains and an abundance of flowing rivers that provide the town and its master craftsmen the optimum conditions and ingredients for creating the sharpest blades in the world. In fact, this relatively small Japanese city of less than 90,000 inhabitants is highly regarded as part of the world’s triumvirate or “Big Three” in cutlery production. According to our tour guide, the industry also endearingly refers to these world leading cities in blade manufacturing as the “Big Three S” that comes from their respective cities: Seki City in Japan, Solingen in Germany, and Sheffield in England.

Traditional and Advanced Production Technology

There is a reason why Seki cutlery is held in such high esteem throughout the world, which is the presence of craftsmen who have inherited the “skills and spirit” from the Kamakura period (1185-1333). They started with Japanese Brade-making and are still correctly inherited today, even though most of the products have become household items.

Today, Seki City is producing various cutlery products including kitchen knives, scissors, beauty care, medical products, and so on. As their varieties expand, these manufacturing technologies are also evolving rapidly. The automation of production through the introduction of AI and robotics has significantly improved their efficiency and quality.

And by weaving the advanced skills of its craftsmen into this, Seki has realized the production of high-performance blades while maintaining mass production. The fact that the Zwilling J.A. Henckels from Solingen has set up a factory for top-quality cutlery in Seki City gives an understanding of the high level of technology here.

#2: KAI Corporation

KAI Corporation, which began in 1908 with the manufacture and sale of pocket knives, was the first Japanese company to produce razor replacement blades and has been the leading razor manufacturer ever since.

Today, the company uses its technological expertise to become a comprehensive manufacturer of cutlery, handling all the cutlery necessary for daily life, including scissors, nail clippers and kitchen knives.

©KAI Corporation, men’s glooming brand AUGER established in 2022

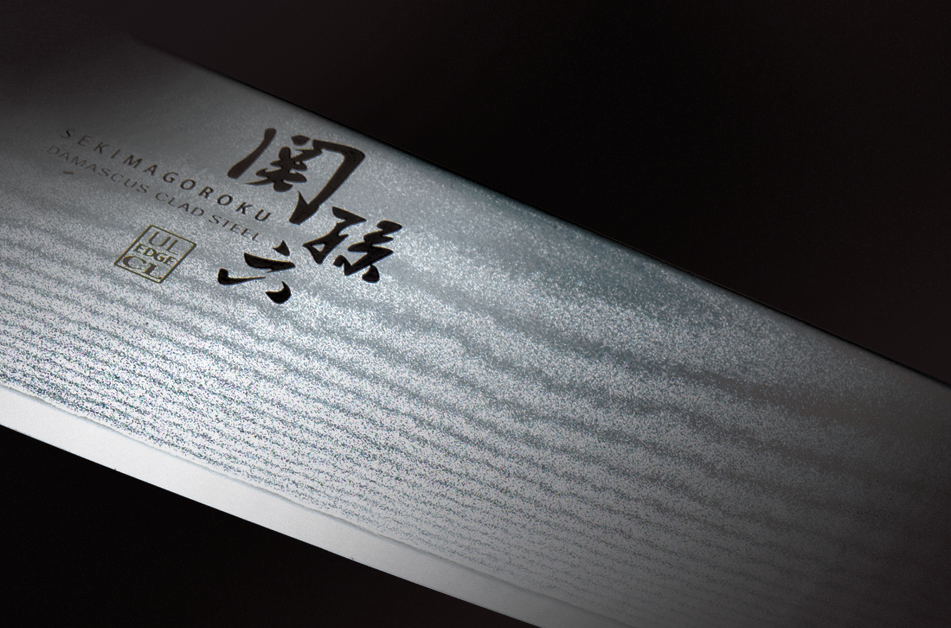

Their focus businesses are medical equipment, glooming equipment including razors and nail clippers, and kitchen knives. Their knives have their roots in Japanese swords and have gained a good reputation worldwide thanks to their delicate sharpness. Its most famous brand is Seki-Magoroku.

Their focus businesses are medical equipment, glooming equipment including razors and nail clippers, and kitchen knives. Their knives have their roots in Japanese swords and have gained a good reputation worldwide thanks to their delicate sharpness. Its most famous brand is Seki-Magoroku.

In Seki City, many craftsmen have been active in making Japanese swords since the Kamakura period (1185-1333). Such craftsmen have been known as Seki Kaji, and Magoroku Kanemoto is considered one of the two major brands of them, along with Magoroku Kanesada.

Kanemoto has been passed down through more than 20 generations, from the Muromachi period through the Edo period to the present day, but it was the second Kanemoto in particular who made the name known throughout Japan.

He developed an original swords forging method and succeeded in creating a Japanese sword that did not break, did not bend and was sharp to the touch. His swords were used by warlords during the Warring States period and became widely famous in the Edo period under the name “Seki-no-Magoroku”.

At the end of the Edo period, people were forbidden to carry swords. This was an opportunity for Seki Kaji to change their profession to that of forging cutlery craftsmmn, and laid the foundations of today’s cutlery industry in Seki City.

Tsubame-Sanjo, Niigata

Tsubame-Sanjo is the combined name of Tsubame City and Sanjo City. Although they are now the most famous metalworking regions in Japan, the origins and specialties of the two cities are different.

The Town of “Kaji”, Sanjo

The Kaji, “鍛治” in Japanese, means the forging of metal to produce a product. In the center of Sanjo, there is a river called the Igarashi River, which had repeatedly flooded since ancient times. This had caused tremendous losses to rice farmers in Sanjo.

In 1625, Seibei Otani, seconded from Edo, invited nail forging craftsmen from Edo to help these farmers and teach them how to make Japanese nails as a side job for them.

When new forging techniques were introduced from the Aizu region in 1661, the range of products expanded from nails to sickles, saws and knives, and full-time forging craftsmen have grew up gradually. With their increase, merchants dealing in metalwork naturally emerged, using rivers such as the Igarashi River and the Shinano River to expand their trading areas. In this way, the “Kaji” town of Sanjo became known throughout Japan.

Today, Sanjo has developed into a metal industry city with a focus on metalworking, including interest craftsmen’s products in their forging tradition, work tools based on forging technology, kitchenware, carpentry tools, measuring, gardening, outdoor, living and housing equipments.

The Transforming Town that had Faced Hardships, Tsubame

The Tsubame area was a sea until about 6 000 years ago, when it became land due to sedimentation from the Shinano and Agano Rivers. As a result, it was a marshy area with poor drainage and flooding, which is why not many people have lived there. The influx of people is said to have started in the 1500s, during the Warring States period, when the area was settled by people who had lost their way in the warring states conflict.

When peace came with the end of the Warring States period, people began to live there permanently. In the Edo period, the need to pay rice as tax to the shogunate arose, but the instability of the rice harvest due to frequent river flooding became a major problem. Therefore, the people shifted their income from agriculture to industry.

At first, same as in the Sanjo area, the main sideline was iron work, such as Japanese nails, but the presence of a copper mountain nearby led to detailed copperwork. This is the beginning of the hammered copperware(“鎚起銅器” in Japanese), which is made from a single sheet of copper. Gyokusendo in Tsubame City is well-known for them.

However, with the end of the Edo period and the massive influx of western culture, Tsubame’s metal industry began to lose out to western imports. A turning point came in 1911. The Tsubame City company Gyokueido began producing Western tableware on order from Tokyo Ginza’s Juichiya-Shoten.

Furthermore, with the start of the First World War, orders for the production of daily necessities began to come in from abroad, where the production of military supplies was a priority, and mass production through the introduction of presses, encouraged by the opening of electricity, was a major factor in their industrial development.

Then, in the Showa period (1925-), Tsubame City began to produce domestic munitions. At the time, the munitions industry was the most advanced technology in Japan, and its acquisition dramatically boosted the technological strength of their industries. It can be said that Tsubame’s industrial development was due to responding to global change flexibly in order to overcome hardships.

#3: GLOBAL

GLOBAL is a brand of kitchen knives manufactured by Yoshida Metal Industry, which started as a Western tableware manufacturer in Tsubame-Sanjo in 1954 and has continued to pursue stainless steel processing technology since its foundation. One of the reaches of this pursuit is this knife brand introduced here.

The main feature of this kitchen knives is that everything from the blade to the handle is stainless steel and in one piece. Due to its overly innovative design, it was not well received in Japan when it was first launched, but it gained popularity at an international trade fair in 1988 and won the Good Design Award in 1990. It has been sold not only in Japan but also worldwide and has become known throughout the world as a knife brand that combines beauty and practicality.

Some of the features are listed below:

-Stainless Working

GLOBAL knives are driven by both sharpness and durability. They use super-hard stainless steel containing molybdenum vanadium, which is also used in medical scalpels. This stainless steel is very rust-resistant and its hardness and strength are less affected by rising temperatures.

-Calm Blade

Unlike most knives, the GLOBAL’s one has clam-shaped blade, which is not straight and sharp from the peak to the edge, but has a gentle curve in the cross-section of the blade towards the edge. This moderate curve reduces friction with the food and also makes it easier to release the cut food.

-Dot Pattern Handle

The knives are easy to wash and hygienic, because their one-piece construction with stainless steel connects the blade and handle seamlessly. Furthermore, the dot pattern on the handle not only serves as a design accent, but also softens the coldness of the metal when gripped.