YAMASA since 1645

Founded in the early Edo period

Yamasa Soy Sauce was founded in Choshi City, Chiba Prefecture, in 1645, at a time when the Edo Shogunate was inaugurated and Edo was undergoing great development. Choshi has a mild climate with cool summers and warm winters, and high humidity, making it an ideal environment for the koji (a type of yeast) that is important for making soy sauce. It is no coincidence that at the same time Yamasa soy sauce was spreading in Edo (now Tokyo), many of Japan’s representative dishes such as Sushi, Tempura, and Kabayaki were born one after another.

The founder of Yamasa Soy Sauce was Gihei Hamaguchi, a native of Kishu (Wakayama Prefecture). Since then, the founding family has kept Yamasa Soy Sauce alive for over 350 years. Among them, Goryo Hamaguchi (1820-1885), the seventh generation, was a businessman and a politician. In particular, during the great earthquake that struck Japan in 1854, Goryo Hamaguchi, who happened to be back in his hometown of Kishu, predicted the coming tsunami based on the abnormal drying up of seawater and well water, and is said to have saved the villagers by calling for their evacuation by throwing fire into the rice paddies. He was praised as “A Living God” by Koizumi Yakumo, and has been handed down to future generations as the hero of the story “Inamura-no-Hi”.

“Yamasa Bacteria” of particular importance

It is said that Yamasa soy sauce is used in more than half of the Japanese restaurants in the Kanto area and more than 70% of the sushi restaurants in Tokyo. In other words, it is the soy sauce of choice for Japanese food professionals.

The process of making soy sauce begins with mixing soybeans, wheat, and koji mold together to make koji. In the case of Yamasa Soy Sauce, they use a special strain of koji called “Yamasa Bacteria,” which has been preserved for over 370 years since the company was founded.

The “Moromi,” which is made by adding salt water to the koji, is then fermented for six months. This is where the artisanal skills of the craftsmen come into play, as they adjust the fermentation slightly according to the season and weather conditions. This is how Yamasa’s soy sauce becomes red and fragrant.

The Yamasa Drop of Freshness

However, once opened and exposed to air, soy sauce oxidizes, darkens in color, and loses its scent and taste. That’s why Yamasa has developed a new product that keeps its freshness longer than ever before, thanks to its packaging and spout. This product is “Drop of Freshness”.

The spout is made of a special thin film that prevents air from getting inside the container, thus preventing the soy sauce from oxidizing. This product also eliminates the hassle of opening and closing the cap-like conventional products, making it stress-free to use.

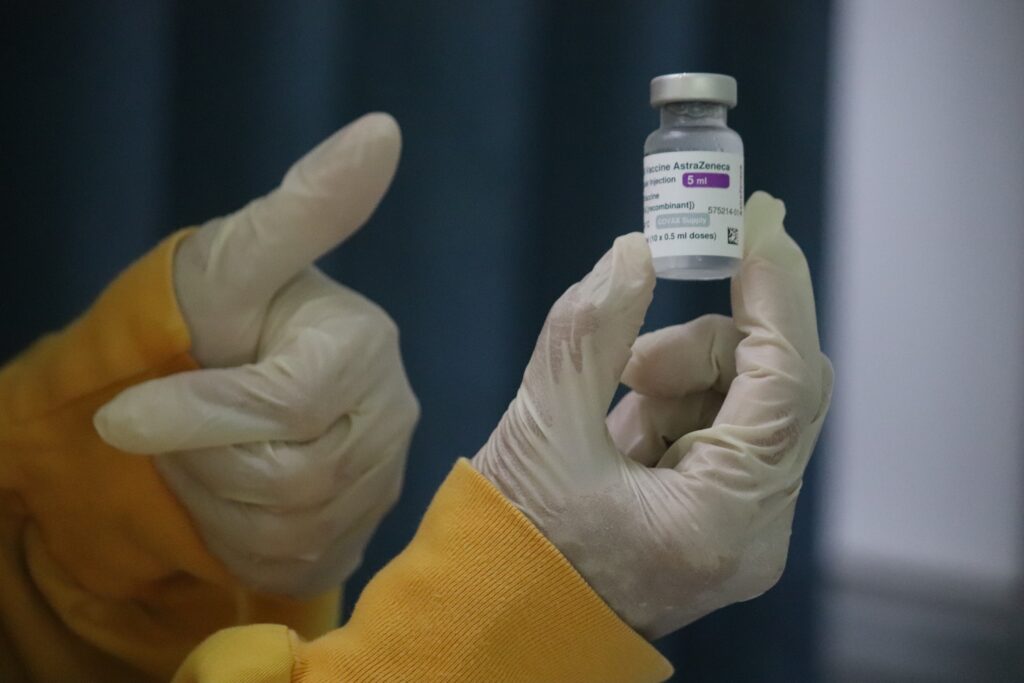

Manufacture of raw materials for COVID-19 vaccines

This long-established soy sauce manufacturer, Yamasa, is contributing to the production of a vaccine against COVID-19, which has been raging since 2020.

“Pseudouridine”

Messenger RNA (mRNA) has been the focus of attention in the widespread use of COVID-19 vaccines. Until now, general vaccines were made by artificially synthesizing pathogenic microorganisms themselves or some proteins and introducing them into the body to prepare antibodies and lymphocytes against them. The new vaccine, on the other hand, injects mRNA, a blueprint for protein synthesis, into the body to create a protein that appears to be a virus in the cells of the human body, making the body recognize it as a foreign substance.

This method has been studied repeatedly since the 1990s because it enables the mass production of vaccines in a short period of time. However, it has been difficult to utilize mRNA because it is degraded as soon as it enters the body and also causes inflammatory reactions in cells.

In 2005, Dr. Catalin Carrico of BioNTech succeeded in getting mRNA into cells without inflammation. The substance used for this was “pseudouridine”.

Yamasa has been exporting this pseudouridine to overseas countries as a pharmaceutical raw material, and in response to the recent pandemic, they are increasing their production capacity to meet the needs of the world.

DNA in pursuit of “Umami”

So why would a soy sauce company be producing pharmaceutical ingredients? In fact, this ingredient is not used in any of their soy sauce or other products.

In fact, Yamasa has been researching nucleic acid-related substances since the 1970s, and since the 1980s they have also been dealing with Pseudouridine, one of the modified nucleic acids. The catalyst for this was the start of the industrial production of nucleic acid-based umami seasonings.

Umami seasonings are ones that make it easy to dissolve and use glutamic acid, inosinic acid, and guanylic acid, the umami ingredients of kelp, bonito flakes, and dried shiitake mushrooms.

The pursuit of taste, which has been handed down from generation to generation since the Edo period, has been passed down as DNA and has led to this contribution.